Thanks to their high energy density, lithium-ion batteries are used in electric cars and electric bikes, for example, as well as for solar energy storage. To improve their safety, durability and performance, energised temperature and climate tests should be carried out and monitored by a CT scanner. Our specialists have developed environment simulation technology for explosion-proof test benches.

First test system of its kind in the world

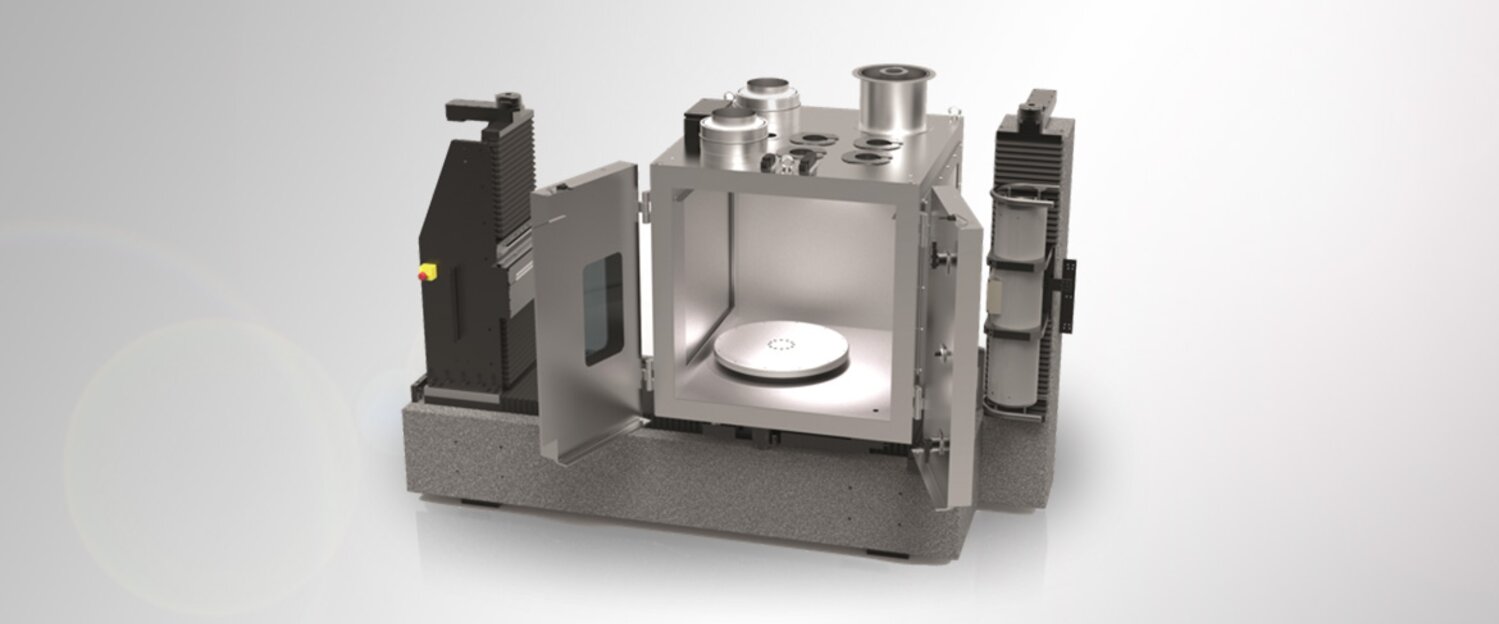

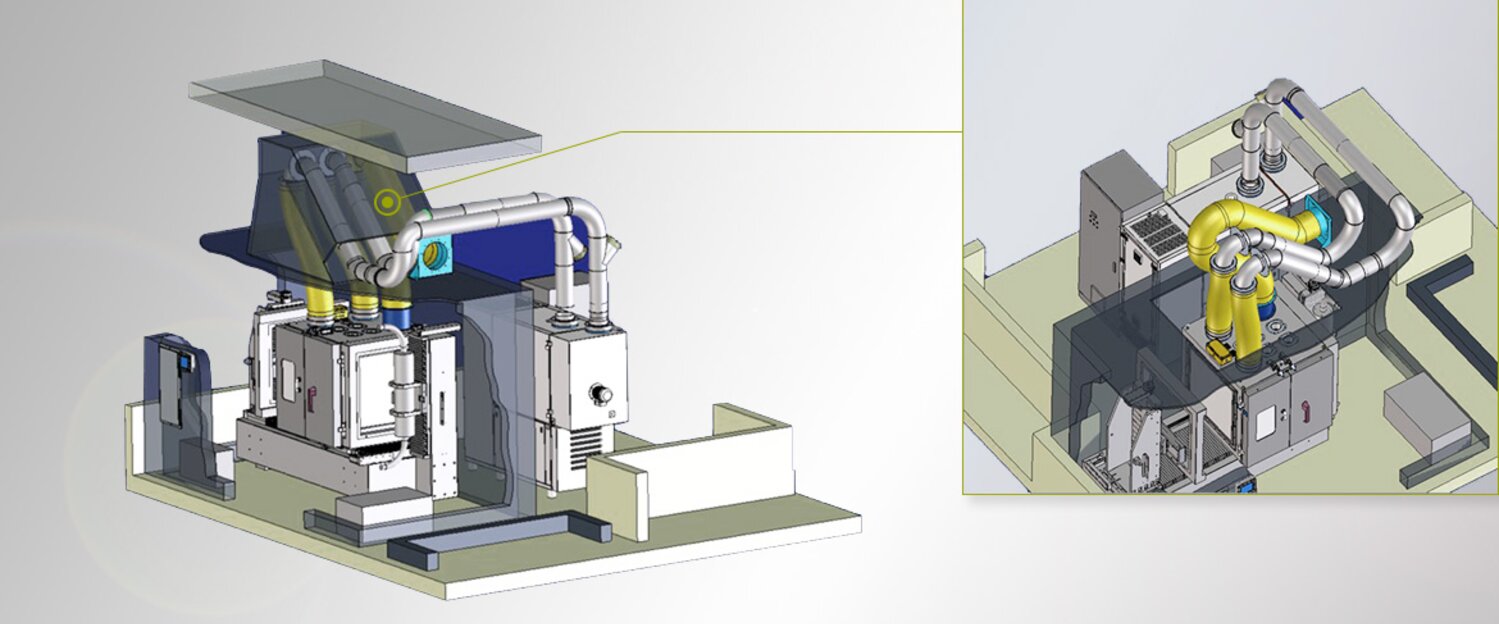

Energised battery modules are tested under different climate conditions – heat, cold, humidity – in order to identify weak spots and optimisation potentials for Li-ion batteries. For these, the DUT is mounted on a rotating plate and examined from all sides by a CT scanner. The complete 3D data for the battery generated in this way allows conclusions to be drawn about its current state.

Explosion-proof design

Since the batteries are subject to extreme stress during testing, there is a risk of exothermal reaction. Such an explosion would endanger battery, testing technology and testing personnel alike. For this reason, an external test space has been constructed for ATEX Zone 1, which is equipped with four gas sensors (H2, O2, CO, HC) and protected up to Hazard Level 6. To protect against the radiation of the CT, the test room is located in a lead-coated installation room, which is supplied with air conditioning via a labyrinth of pipes. In case of fire, the test room is flooded with nitrogen (N2). If rapid pressure equalisation is required, this is achieved via a pressure relief flap.

EU project for development of standard

The test space is a project operated by the EU's joint research facility in Petten, Holland. This offers researchers access to cutting-edge technical equipment in order to research optimisation possibilities for battery performance and safety and to develop standards, which the Fraunhofer Institute has been commissioned to do. As a partner to the specialists for industrial CT scans, diondo, we have planned and realised the climate testing section of the system, including all safety devices.

Contact:

Malcolm Youll

Managing Director

01509 631 595

malcolm.youll@weiss-technik.com