In 2018, Weiss Technik completed a substantial project to design and build a specialist controlled environment facility at the University of Liege at Gembloux (ULG). This challenging project called for the development of a chamber to simulate growth conditions close to natural conditions. This was to further explore communities of plants, animals and microbiota in agricultural and natural ecosystems models. In particular, the aim was to study field crops and the effect of global warming on their physiology and their interactions with the biotic and abiotic environment.

Weiss Technik has a long and successful history of finding the right climatic simulation solutions for organisations involved with scientific investigations of plant growth, insect growth, tissue cultures, seeds and other microbiological applications. We have wide-ranging products available, including specialist climatic cabinets and rooms and highly advanced lighting solutions that facilitate the most advance research programmes.

Our particular strengths are realised when working alongside university laboratories, meeting and often exceeding their expectations. In this example, we worked closely with the University of Liege to develop and validate an advanced installation that focused on the simulation of natural light. Throughout the process, our specialists developed prototypes and an actual demonstration unit that ULG could test to validate the system.

Ecotron project detail in brief

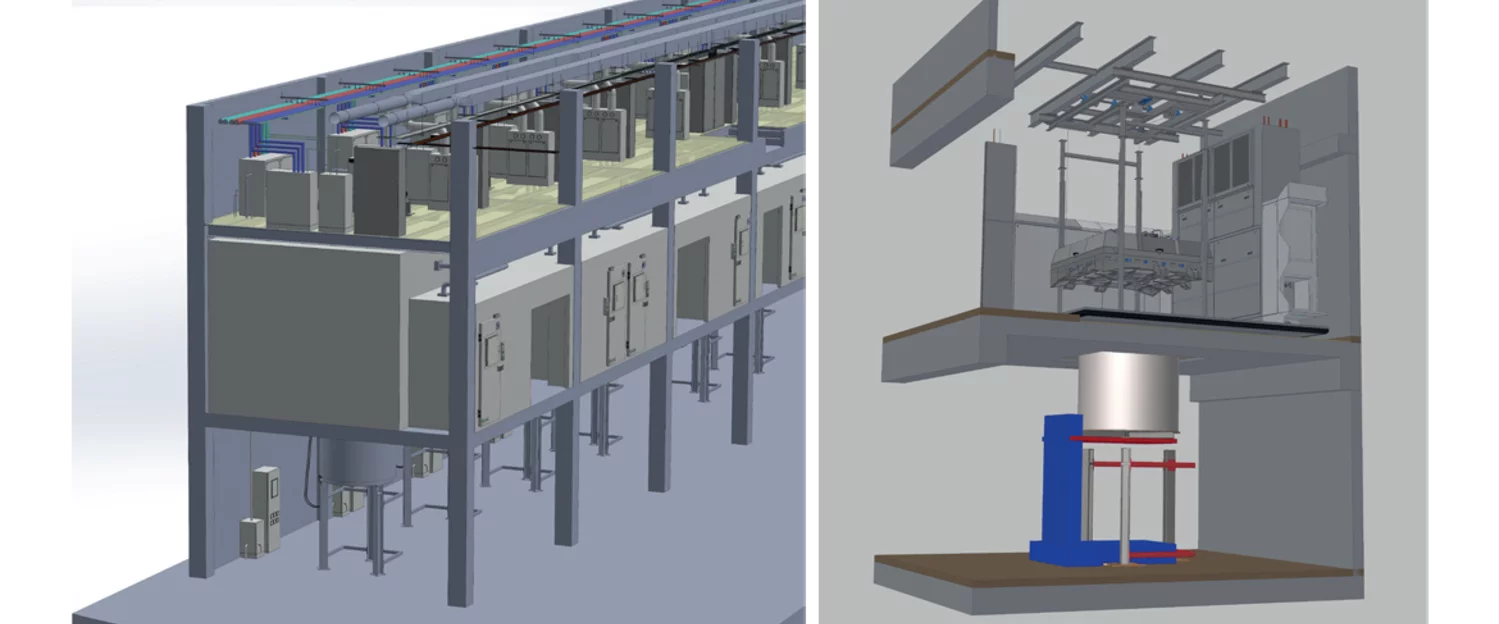

- 6 Identical chambers in new purpose-built building, including centralised cooling and ventilation systems

- Integration of bespoke SCADA software

- Control of Temperature, Humidity, Radiation, CO2, O3, Air velocity, Irrigation and Air Pressure (for containment)

Lighting System Specification

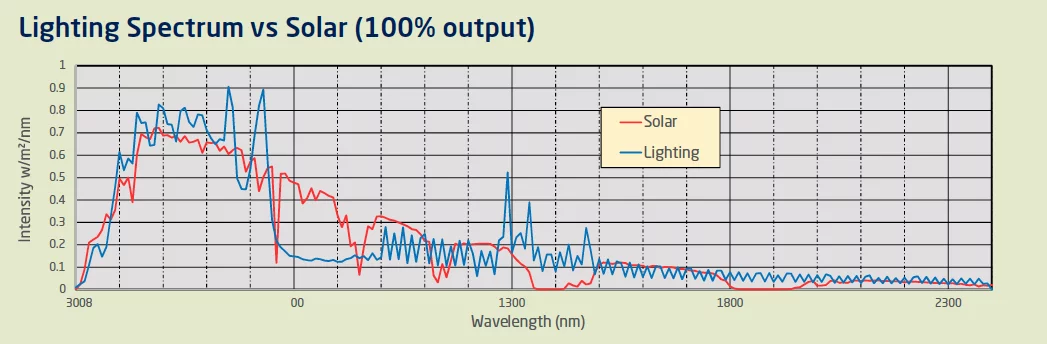

- ULG required a lighting system to simulate natural sunlight

- Ultra-violet, visible (PAR) and infra-red components to be included

- Compliance with specification to be demonstrated by numerical analysis of the system compared to a reference solar spectrum data set.

The Solution

Our solution to meet the challenging lighting specification led us to selecting Light Emitting Plasma technology as the principle light source. Importantly, this light source included sufficient UV-A radiation. However, it was apparent that the red, far-red, and near infra-red parts of the spectrum would require supplementary sources, so monochromatic LED sources were used to supplement the red and farred light. Additionally, tungsten-halogen lamps were used to provide the required infra-red heat.

The physical arrangement of the lamps was developed over several iterations using simulations, before a full-scale prototype was constructed, which allowed final optimisation of the light homogeneity through multi-axis adjustment. Analysis of the light spectrum was made possible following investment in a state-of-the-art spectroradiometer, enabling simultaneous measurement of the light spectrum over the whole range.

Finally, a sophisticated control strategy was developed and tested to allow the full range of light intensities to be achieved whilst maintain the criteria for homogeneity and spectrum.

For further details, please contact us.